Pure Tea, Pure Moments

Enjoy the delicate flavors of hand-picked leaves, brewed to refresh your day.

Tea Collection

Top Selling

All

White Tea

Black Tea

Green Tea

Tea Set

Guizhou Decaffeinated Loose Black Tea 500g

Regular price

$29.00 USD

Guizhou Baihao Yinzhen Tea 500g

Regular price

$141.00 USD

English ceramic teacup

Regular price

$11.50 USD

China Guizhou High Mountain White Tea

Regular price

$18.99 USD

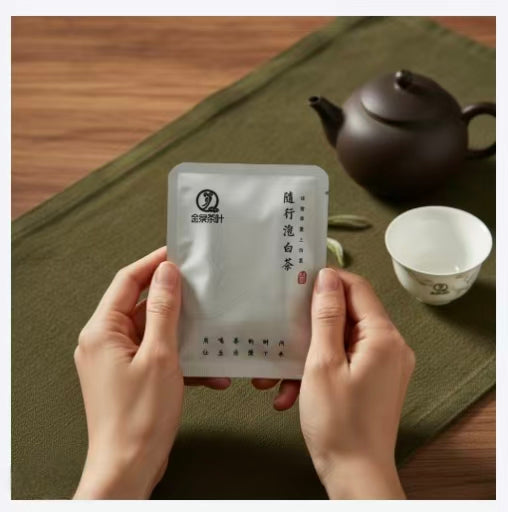

Travel-sized white tea, eight pieces per box, 5g each, total weight 40g

Regular price

$15.44 USD

Guizhou Baihao Yinzhen Tea 500g

Regular price

$141.00 USD

China Guizhou High Mountain White Tea

Regular price

$18.99 USD

Private black tea individual small package a whole box of 80g

Regular price

$23.68 USD

Guizhou Decaffeinated Loose Black Tea 500g

Regular price

$29.00 USD

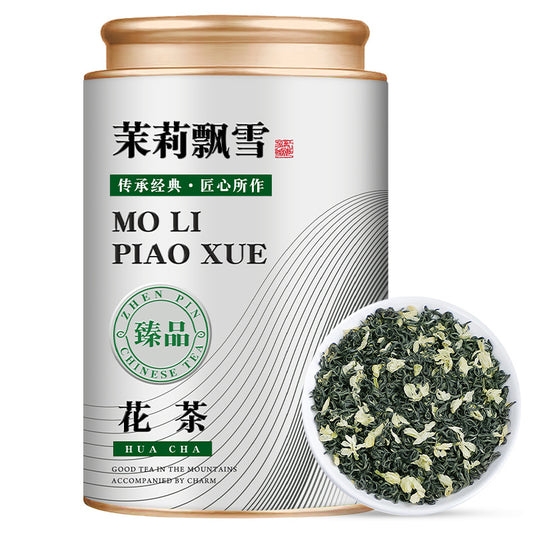

Jasmine Tea Premium Strong Aroma Tea5New Tea Jasmine Snow Green Tea Canned for Personal Use

Regular price

$25.60 USD

+250g Premium Jasmine Snowfall~

+500g Premium Jasmine Snowfall~

+250g Super5Star Jasmine Snowfall~

+501g Super5Star Jasmine Snowfall~

Songyang White Tea2025New Tea Pre-Rain Tender Buds Loose Gift High Mountain Green Tea Not from Anji Origin Longjing Wholesale

Regular price

$22.28 USD

100g

50g

250g

500g

Duyun Maojian New Tea Authentic Premium Tender Bud Roasted Green Tea Loose Leaf Guizhou High Mountain Cloud Mist Pre-Qingming Tea

Regular price

$21.09 USD

One-pack【250g】

Two-pack【500g】

Four-pack【1000g】

【Super】One-pack 250g

【Super】Two-pack 500g

【Super】Four-pack【1000g】

High Mountain Green Tea Maojian 2025 New Tea Strong Aroma Loose Leaf Tea Bagged Authentic Spring Tea [Newcomer]

Regular price

$12.25 USD

Green tea [1 bag*250g]

Maojian [1 bag*250g]

Green tea [1 bag*100g]

Rotatable Lid Bowl with Hovering Function, High-End Sheep Fat Jade Three-Talent Lid Tea Bowl, Tea Set, White Porcelain Handheld Tea Brewing Pot

Regular price

$18.00 USD

【180ML】Hovering Covered Bowl-White jade-Fujuzhu

Under-capacity【180ML】Hovering Covered Bowl-White jade-Lonely Fishing in the Cold River

Under-capacity【180ML】Hovering Covered Bowl-White jade-Ink Painting Mountain Landscape

Under-capacity【180ML】Hovering Covered Bowl-White jade-Chinese White

Jade Porcelain with Gold Rim Worry-Free Gong Cup-Fujuzhu

Worry-Free Gong Cup Made of Sheep Fat Jade Porcelain-Pure White

Lamb Fat Jade Porcelain Gold-Edged Tea Cup-Fujuzhu

Mutton Fat Jade Porcelain Tea Cup-Pure White

High-end Ru Kiln Ceramic Master Cup Retro Rotating Tasting Cup Personal Tea Cup Gift Box Single Cup Gift

Regular price

$25.31 USD

Handheld Cup-Green

Arhat Cup-Green

Abdominal Cup-Green

Handheld Cup-Yellow

Arhat Cup-Yellow

Abdominal Cup-Yellow

Handheld Cup-Pink

Arhat Cup-Pink

Abdominal Cup-Pink

Gift Box

Jade Porcelain Kung Fu Tea Set White Porcelain Home Office Brewing Suspended Tea Lid Bowl Ceramic Tea Cup Tea Tray Complete Set

Regular price

$30.93 USD

FY9White Porcelain with Head Sheep Fat Jade+Tea Tray-Travel Packaging

FY9White Porcelain with Head Sheep Fat Jade-Glass Men's Cup Model+Tea Tray-Travel Packaging

FY9White Porcelain Landscape with Head of Sheep Fat Jade+Tea Tray-Travel Packaging

FY9White Porcelain Landscape with Head of Sheep Fat Jade-Glass Men's Cup Model+Tea Tray-Travel Packaging

FY9White Jade Porcelain Rich Bamboo+Tea Tray-Travel Packaging

FY9White Jade Porcelain Rich Bamboo-Glass Men's Cup Model+Tea Tray-Travel Packaging

FY9Snow Scene of White Porcelain with Head of Sheep Fat Jade+Tea Tray-Travel Packaging

FY9Snow Scene of White Porcelain with Head of Sheep Fat Jade-Glass Men's Cup Model+Tea Tray-Travel Packaging

FY9White Porcelain Mist Mountain with Head Sheep Fat Jade+Tea Tray-Travel Packaging

FY9White Porcelain Mist Mountain with Head Sheep Fat Jade-Glass Men's Cup Model+Tea Tray-Travel Packaging

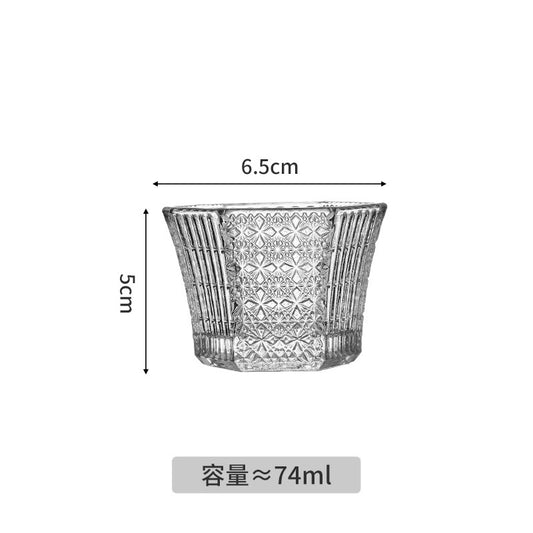

Creative Nordic Style Embossed Hammered Glass Small Tea Cup Teapot Set Sake Spirits Small Shot Glass Hexagonal Cup

Regular price

$15.89 USD

Embossed Pattern Hexagonal Cup【74ml】

Glacier Small Tea Cup【80ml】

Round Belly Frosted Tea Pot【180ml】

Glacier Pattern Tea Pot【200ml】

Complete Tea Set Portable Kung Fu Ru Kiln Ancient Charm Set with Tea Tray Outdoor Ceramic Quick Tea Cup Company Business Gift

Regular price

$37.96 USD

Ru ware/Ancient Style Teapot+6Bucket Hat Cup+Tea Pot+Rectangular Plum Blossom Black Tea Tray/Gray Leather Bag

Ru ware/Ancient Style Teapot+6Bucket Hat Cup+Tea Pot+Rectangular Plum Blossom Black Tea Tray/Blue Leather Bag

Ru ware/Ancient Style Teapot+4Bucket Hat Cup+Tea Pot+White Oval Plate+Tea Towel Tea Clip/Brown oval bag

Ru ware/Ancient Style Teapot+4Bucket Hat Cup+Tea Pot+White Oval Plate+Tea Towel Tea Clip/Blue Oval Bag

Ru ware/Ancient Style Teapot+4Bucket Hat Cup+Tea Pot/Zhenzang Gift Box

Ru ware/Ancient Style Teapot+4Bucket Hat Cup+Tea Pot/Square Bag

Ru ware/Ancient Style Teapot+4Bucket Hat Cup+Tea Pot/Thousand Miles of Rivers and Mountains Gift Box

Ru ware/Ancient Style Teapot+3Bucket Hat Cup+Tea Pot+Blue Tea Towel/Little Brown Bag

Ru ware/Ancient Style Teapot+3Bucket Hat Cup+Tea Pot+Blue Tea Towel/Little Blue Bag

Ru ware/Ancient Style Teapot+3Bucket Hat Cup+Blue Tea Towel/Little Black Bag

Ru ware/Ancient Style Teapot+3Bucket Hat Cup+Tea Pot+Blue Tea Towel/Big Black Bag

Ru ware/Ancient Style Teapot+3Bucket Hat Cup+Blue Tea Towel/Little Yellow Bag

Ru ware/Ancient Style Teapot+3Bucket Hat Cup+Tea Pot+Blue Tea Towel/Big Yellow Bun

Tea Set Suit B&B Kung Fu Teapot Ceramic Hotel Restaurant Souvenir Chain Company Cup Corporate Gift for Gifting

Regular price

$33.46 USD

Single teapot

1Pot+2Cup

1Pot+4Cup

1Pot+6Cup

1Pot+4Cup+Tray

1Pot+6Cup+Tray

(Gift Box)1Pot+6Cup+Tray

a Pot4Cup+Square Tea Tray

a Pot4Cup+Round Tea Tray

a Pot8Cup+Square Tea Tray+Includes Pot Mat

a Pot8Cup+Round Tea Tray+Includes Pot Mat

(Gift Box)One pot four cups+Round Tea Tray

Teapot Semi-Automatic Stone Mill Kung Fu Tea Set Purple Clay Household Tea Brewer Simple Fortune Comes Lazy Person Brewing

Regular price

$20.51 USD

Three-legged Stone Mill Set with Fair Cup Yuanshan

[Stone Mill Black Clay] 8-Piece Set

【8 Pieces】 Bright Signature Quiet Fighting

【Volume】Man Teng-Ying

【Poetry and Distance】Stone Mill

Peace of Mind Blue Porcelain [Stone Mill]

[Purple Clay Hundred Blessings] 8-Piece Set

【Jingxin Porcelain】Glaze Bright

Green Bamboo Section High Rise

【Steamed Steamed Daily】Mustard Greens

Change to [Blue Sky Blue] Kiln

Stone Mill [Landscape Sentiment]

Jinyu Mantang Dong Liang

Bright and Full【Hot Sale】

Shimodo Higashifudai Tengge

Heart to Heart Quiet【White】

Dragon Light Mountain Color

Quiet Mountain Heart One Side

8 Pieces Bright Lotus Black

Stone Mill [Hanjiang Jade Fishing]

Stone Mill Mountain Far Coarse Pottery 8-Piece Set Original Pottery

Stone Mill Quiet Scene Coarse Pottery 8-Piece Set Original Pottery

Stone Mill Leaf Lotus Coarse Pottery Six Cups Original Pottery

Original Color Taoshan Yuan+ Fairness Cup

Three-legged Stone Mill Shanyuan Original Color Pottery

Three-legged Stone Grinds the Mind Pure Color Ceramic

Three-legged Stone Mill Purple Original Color Clay Pottery

Three-legged Stone Mill Matching Tea Cup [Set of 6]

Three-legged Stone Mill Qing Yun Original Color Ceramic + Fairness Cup

Three-legged Stone Polished Pure Color Ceramic + Fairness Cup

Three-legged Stone Ground Purple Original Color Clay Fairness Cup

Pfaff Purple with Tea Sea

【Pfaff Purple】Three-Legged Stone Mill

Ru Kiln Suspended Three-Talent Covered Bowl Tea Cup High-End Tea Bowl with Lid for Brewing Tea Kung Fu Tea Set Sea Water Jiangya Ceramic Tea Offering

Regular price

$19.68 USD

YS Ru Kiln Ocean Wave Cliff Suspended Lid Bowl

YS Ru Kiln Ocean Wave Cliff Suspended Lid Bowl+2Cup

YS Ru Kiln Ocean Wave Cliff Suspended Bowl Gift Set

YS Ru Kiln Ocean Wave Cliff Suspended Lid Bowl+2Cup+Begonia Glass Tray

YS Ru Kiln Ocean Wave Cliff Suspended Lid Bowl+2Cup-Gift Box

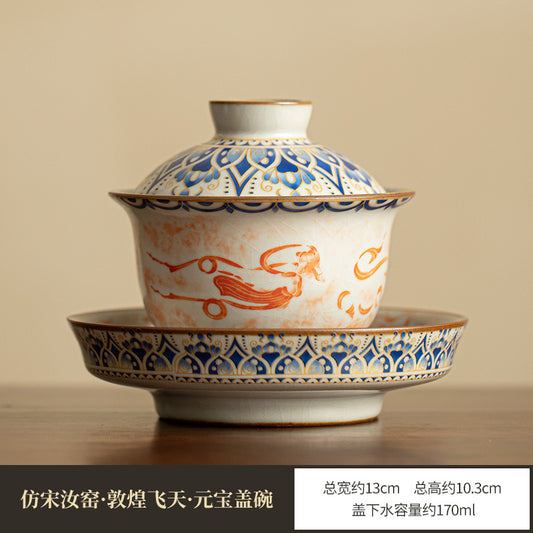

Ru Kiln Ceramic Rubbing Flying Sky Dunhuang Gaiwan Kung Fu Tea Set Tea Cup Three-Talent Gaiwan Douli Horse Hoof Gaiwan Tea Brewing

Regular price

$29.24 USD

Imitation Song Dynasty Ru Kiln—Dunhuang Feitian Yuanbao Covered Bowl

Imitation Song Dynasty Ru Kiln—Dunhuang Feitian Douli Covered Bowl

Imitation Song Dynasty Ru Kiln—Dunhuang Feitian Master Cup

Imitation Song Dynasty Ru Kiln—Dunhuang Feitian Horseshoe Cover Bowl

Imitation Song Dynasty Ru Kiln—Dunhuang Feitian Little Dragon Egg Cup

Imitation Song Dynasty Ru Kiln—Dunhuang Feitian Drawstring Cup

Imitation Song Dynasty Ru Kiln—Dunhuang Feitian Xishi Teapot

Imitation Song Dynasty Ru Kiln—Dunhuang Feitian Filter

Imitation Song Dynasty Ru Kiln—Dunhuang Feitian Justice Cup

Imitation Song Dynasty Ru Kiln—Dunhuang Kweichow Moutai-Bamboo Hat Covered Bowl8Headgear Set Gift Box

Imitation Song Dynasty Ru Kiln—Dunhuang Kweichow Moutai-Horseshoe-shaped Covered Bowl8Headgear Set Gift Box

Imitation Song Dynasty Ru Kiln—Dunhuang Kweichow Moutai-Yuanbao Covered Bowl8Headgear Set Gift Box

Single Cup Gift Box

Single Pot Gift Box

Matching Cup Gift Box

Three Talents Covered Bowl Gift Box

Gaiwan(a Pot)Two Cup Gift Box

Gaiwan(a Pot)Four Cup Gift Box

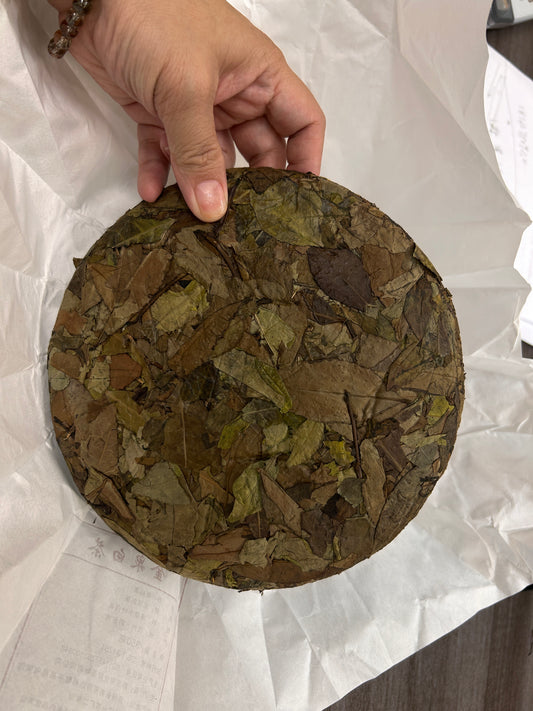

Premium Teas from Ancient Trees

Handpicked from centuries-old tea trees, our teas offer unmatched aroma, rich flavor, and exquisite quality in every cup. Perfect for connoisseurs and thoughtful gifts alike.

About Us

The Charm of Qian Tea, Growing in Harmony with Nature

Guizhou Minshun Tea Co., Ltd. was born in the era when the ecological tea regions of Qiandongnan rose in value and consumers increasingly demanded high-quality specialty teas......

Mika

Group Vice President

WhatsApp: +86 189 2572 5737

Judy

Business Manager

WhatsApp: +86193 1653 8721

Bella

Business Manager

WhatsApp: + 86 182 1232 8770

![High Mountain Green Tea Maojian 2025 New Tea Strong Aroma Loose Leaf Tea Bagged Authentic Spring Tea [Newcomer]](http://guizhouminshun.com/cdn/shop/files/c170c996-2261-41e2-9567-8a92ae1d1175.jpg?v=1762843486&width=533)

![High Mountain Green Tea Maojian 2025 New Tea Strong Aroma Loose Leaf Tea Bagged Authentic Spring Tea [Newcomer]](http://guizhouminshun.com/cdn/shop/files/6fcab224-658b-4b52-b480-7ea23a599dc5.jpg?v=1762843486&width=533)